Commercial Fertigation for Cannabis Crops

Fertigation & Irrigation Systems

Fertigation comes from the combination of the words fertilization and irrigation. Also known as nutrient injection, fertigation involves the injection of fertilizers and other nutrients into an irrigation system that feeds crops. Fertigation systems can completely automate the process of mixing nutrients and watering plants. This can free up time for the head grower and other team members, allowing them to focus on alternative tasks. Fertigation benefits the crops through increased nutrient absorption and the ability to microdose feeds multiple times per day leading to reduced fertilizer usage and decreased water consumption. Some fertigation systems provide total control over consistent application of nutrients at a precise time and rate determined by the cultivator. Soil moisture sensors can be included in a fertigation system to either monitor moisture levels or activate the system, so that your plants are never too dry or hungry. Cobau Engineering offers a variety of fertigation systems with different levels of automation and features. Each system combines exact proportions of nutrients with a measured amount of water to each plant. If you have any questions regarding these systems and which one would work best for your operation, do not hesitate to reach out.

CALL TODAY (313) 498-5002

Request A Proposal

"*" indicates required fields

AUTOMATED IN-LINE INJECTION SYSTEMS

DIRECT INJECTION: Our most popular product is an automated direct injection Fertigation Machine called the Nutrix Bypass System. This is a fertigation system that stores recipes, pumps an exact recipe of nutrients to the plants, and monitors the solution being delivered. It also eliminates the production of individual batches of irrigation water and the need for batch tanks. Instead, the system uses advanced controls to dial in the correct recipe and once stabilized, it is sent out to feed. The fertigation system monitors the electrical conductivity (EC) and pH of the feed solution and even makes automatic adjustments to maintain the predetermined setpoints. This type of system is extremely popular with growers who like to vary the feed concentration to their plants depending on the age of the crop. It has zone controls so that crops in different stages of growth can be fed off the same system without any additional work. Many growers use this system’s internet capabilities to feed and monitor their plant remotely.

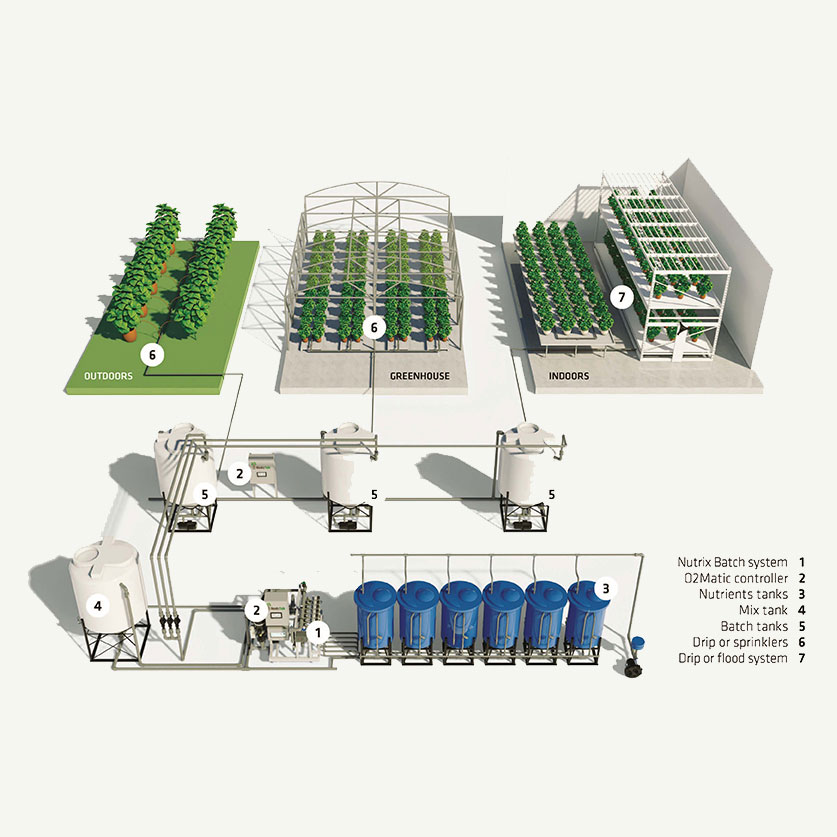

AUTOMATED BATCH SYSTEMS

Many growers prefer to use a batch system like the Nutrix Batch System to automate their irrigation process. Using a series of storage tanks, this type of fertigation system premixes the recipe until the EC and pH reach the desired values determined by the cultivator. The water is then pumped from the storage tanks to the crop on an irrigation schedule set by time or by moisture sensors. This allows for feedings in many short bursts that can be triggered using those sensors. Some users have used this microdosing feature to water their crops up to thirty five times a day. This method of watering increases oxygen availability to the roots and ensures the plant always has what it wants. Case studies have shown that this increases the plant growth and even the cannabinoid levels of a cannabis crop. Cultivators can use this system to monitor their crops and control their irrigation from anywhere in the world with internet access.

MECHANICAL INJECTION SYSTEMS

For some cultivators, the best option is a mechanical direct injection system like those made by Dosatron. These systems work best with crops that have consistent nutrient requirements. They can save the grower time and labor by simplifying nutrient addition for recipes that do not change constantly. Each nutrient requires a doser that draws from a nutrient tank and mixes with the water as it passes through until ready to feed. This fertigation system is more affordable and can be easier to use. The installation can easily be completed by the cultivation team with the support of Dosatron and Cobau Engineering.

Cobau Engineering

20233 Mack Ave., Grosse Pointe Woods, MI 48236